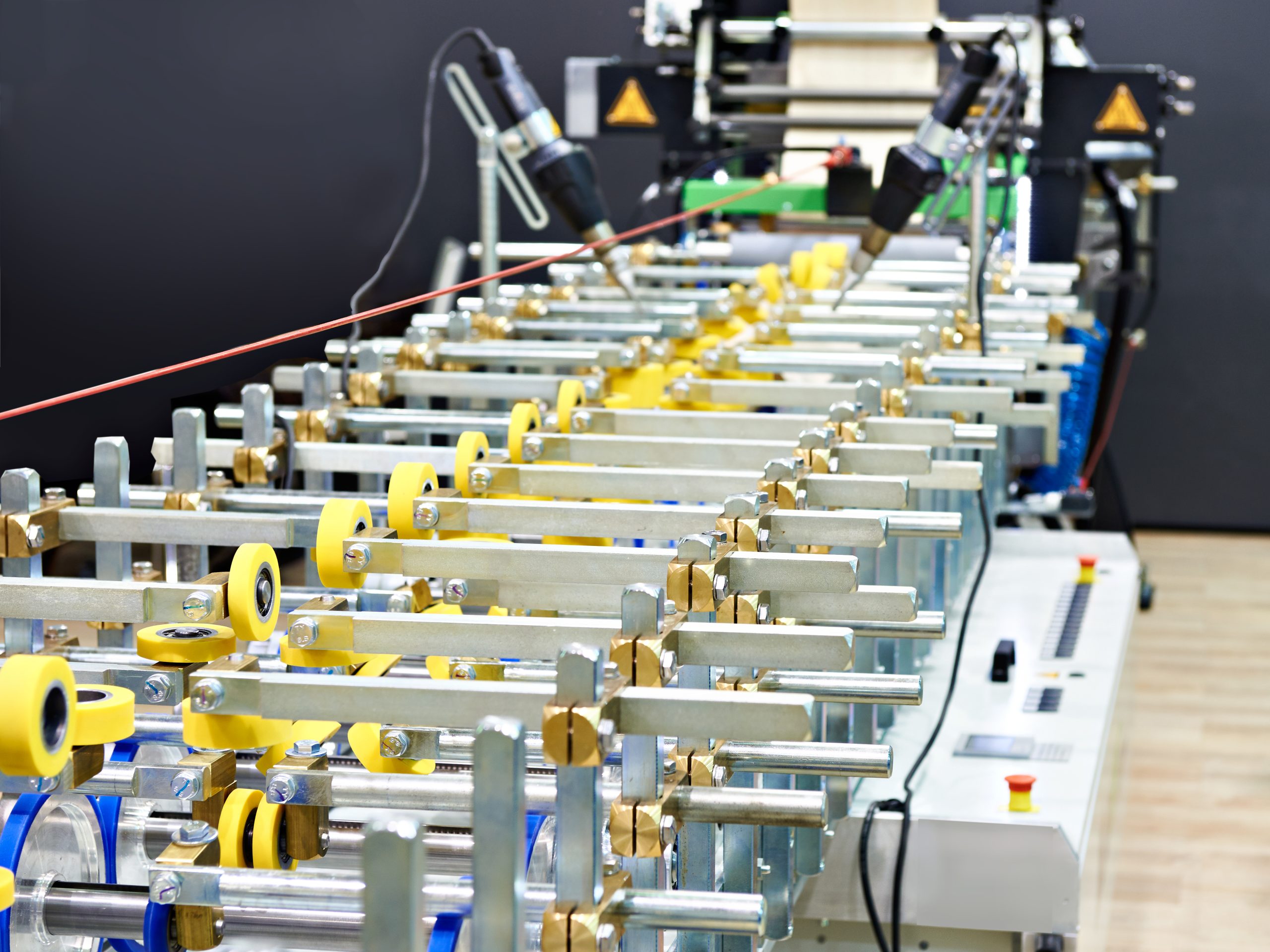

The lamination industry is a specialized technical sector where equipment performance and reliability directly determine the quality of the finished product. This industrial technique requires tailor-made solutions to ensure adhesion, uniformity, and durability of the applied coatings.

Lamination consists of applying a thermoplastic decorative film to profiles, providing a wide variety of aesthetic finishes while preserving the structural properties of the base material.

The Industrial Lamination Process

Lamination is a sophisticated industrial process that transforms the appearance of profiles through the application of a decorative film. The process requires perfect control of several critical parameters to guarantee the quality of the final result.

Surface preparation is the first crucial step. Before applying the film, the surface of the PVC (or other) profile is carefully cleaned and prepared to ensure optimal adhesion. This stage directly conditions the quality of the final bond and the durability of the coating.

Lamination is carried out under controlled pressure and high temperature to ensure homogeneous and resistant adhesion. The adhesives used are adapted to the constraints: polyurethane (PU) for versatility, or high-temperature formulations for the most demanding applications.

Major Technical Challenges

Thermal and Mechanical Constraints

The lamination industry faces multiple technical challenges that require high-performance equipment. Application temperatures can reach 600°C in extreme conditions, while roller pressures vary between 2 and 8 bars depending on the application.

The main issues include:

- Thermal deformation of rollers under heat

- Premature wear of contact surfaces due to friction

- Vibrations generated by variable line speeds depending on the application

- Misalignments caused by differential expansions

Adhesion and Quality Issues

The most common defects in lamination processes often result from poor control of application parameters. Insufficient adhesion causes premature delamination, while thermal variations lead to dimensional distortions.

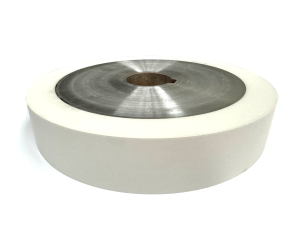

Roller wear generates surface irregularities that directly affect the visual quality of the finished product. Surface contamination also represents a constant challenge, especially in industrial environments where airborne particles can compromise the adhesion of the decorative film.

ENRI’s Technical Solutions: Expertise and Innovation

With more than 35 years of experience, ENRI offers advanced technical solutions specifically designed to meet the demands of the lamination industry. The company’s expertise covers all encountered challenges, from roller coverings to the manufacturing of custom-engineered technical parts.

Range of Specialized Coatings

| Material | Max. Temperature | Main Applications |

| High-Temperature Silicone | 280°C | High-temperature pressure rollers |

| Polyurethane | 120°C | Guide and drive rollers |

| Technical Rubber | 180°C | Standard application rollers |

| Composites | 250°C | Customized specialized applications |

High-temperature silicone coatings provide exceptional resistance to pressure and temperature application conditions. They maintain their elastic properties even at elevated temperatures, ensuring constant adhesion and uniform pressure transmission.

Polyurethane is characterized by its resistance to physical impacts, greases, oils, and acids. This versatility makes it the preferred choice for demanding applications with significant mechanical stress.

Preventive Maintenance and Optimization

Regeneration Approach for Equipment

ENRI offers an innovative preventive maintenance approach based on equipment regeneration. Used rollers can be regenerated by stripping the worn coating, treating the metal core, applying a new coating, and performing precision grinding, ensuring performance identical to new equipment.

This strategy significantly extends equipment service life while reducing replacement costs.

Key benefits include:

- Reduced maintenance costs

- Minimization of unplanned production downtime

- Maintenance of optimal line performance

- Improved environmental footprint

Advanced Performance and Resistance

Superior Technical Characteristics

- Thermal resistance: ENRI coatings withstand high temperatures without losing mechanical properties, ensuring constant adhesion and minimal wear even under extreme conditions.

- Extended chemical compatibility allows these coatings to be used with a wide range of cleaning and maintenance products, simplifying upkeep procedures.

Multi-Sector Applications

ENRI’s solutions are applied across many industrial sectors. This versatility results from ENRI’s ability to precisely adapt formulations to the specific constraints of each application.

Environmental Commitment

In 2023, ENRI officially launched an CSR (Corporate Social Responsibility) initiative, integrating eco-responsibility into all aspects of production. Concrete actions include the integration of recycled materials, waste reduction, and improved energy performance.

The development of bio-based materials meets the growing demands for environmental compliance while maintaining the high technical performance required by industry.

Technical Support and Assistance

Expertise Services

The ENRI technical team supports clients throughout all project phases, from analyzing specifications to equipment commissioning. The dedicated design office offers tailor-made solutions adapted to the specific constraints of each installation.

Services include:

- Rapid technical study

- Fast prototyping and performance validation

- Maintenance team training

Certifications and Quality

ENRI productions comply with the strictest certifications.

Conclusion: Industrial Performance and Reliability

In the lamination industry, equipment performance depends directly on the quality of roller coverings and technical parts. ENRI provides tailor-made, durable solutions designed for extreme conditions, improving productivity while reducing wear and maintenance costs.

The technical expertise developed over more than three decades, combined with continuous investment in innovation, positions ENRI as the reference partner for demanding manufacturers.

The ability to provide customized solutions, supported by responsive technical services, ensures the optimization of production performance.

Contact our experts for a personalized technical analysis and tailored support for your industrial lamination projects.

Need a technical solution?

Trust ENRI for your industrial coatings and molded technical parts.

Contact our experts →