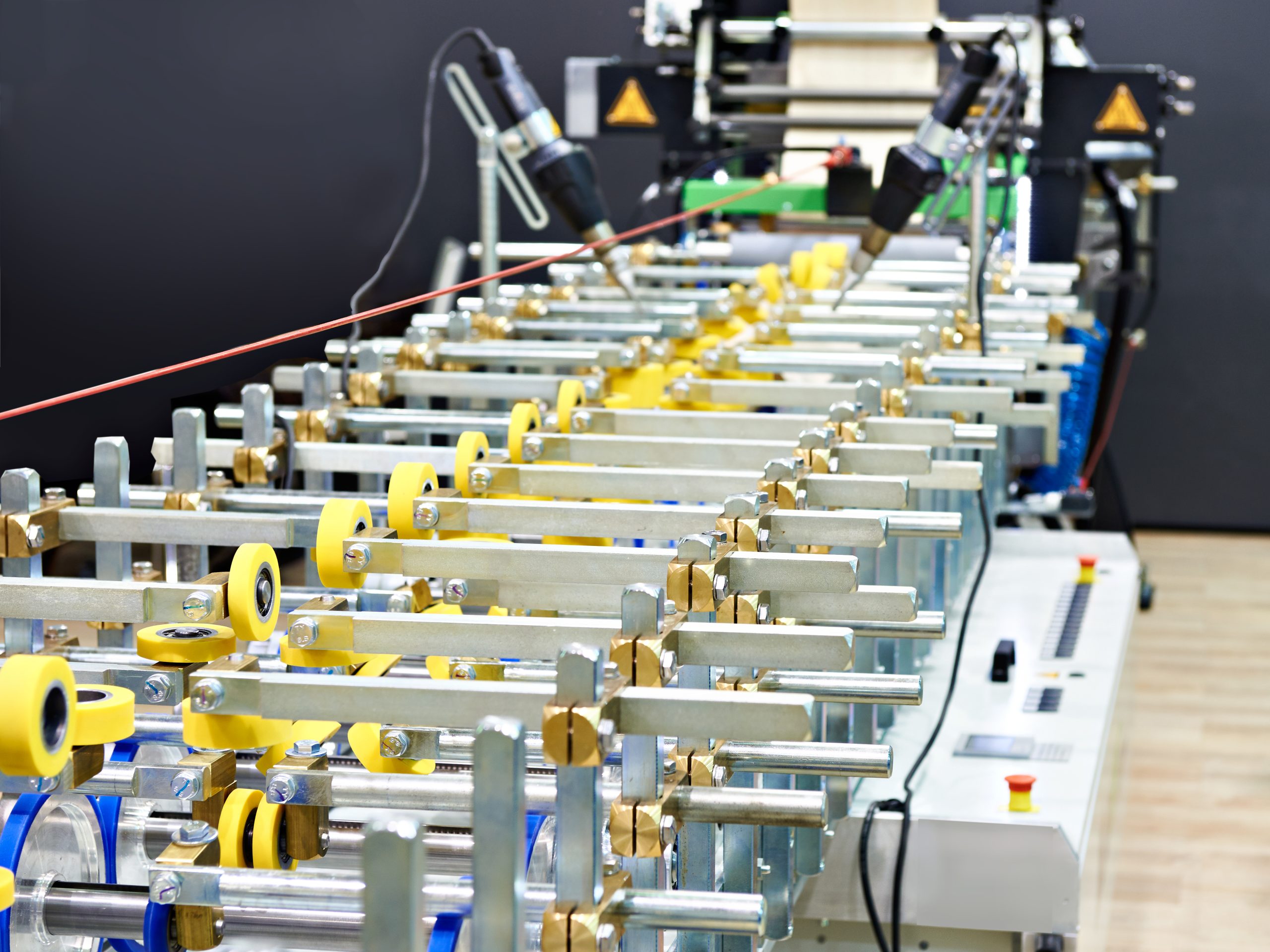

In the packaging industry, every production stage requires precision and reliability

Behind high-performance and uninterrupted production lines are components that may seem discreet but are absolutely essential: industrial rollers. Their coating directly affects the quality of the final product, the stability of the process and the lifetime of the machine.

For more than 35 years, ENRI has supported packaging manufacturers with custom roller coverings in silicone, polyurethane and technical rubbers, engineered to meet the specific constraints of each application: plastic film extrusion, calendering, coating, lamination, conveying and winding.

Understanding the role of rollers in packaging

Extrusion rollers: Extrusion rollers pull the plastic film at the correct speed and contribute to progressive cooling. The synchronisation between the die output and the roller speed determines the final film thickness. These rollers must withstand temperatures up to 150–200 °C and maintain uniform pressure across the full width. Polyurethane is ideal thanks to its abrasion resistance and mechanical stability.

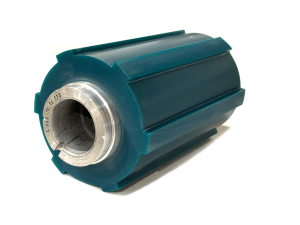

Calendering rollers: Used to produce sheets or films with precise thickness and a controlled surface finish. Temperature, roller speed and surface treatment determine whether the material ends up glossy, matte or textured.

Coating and laminating rollers: These rollers apply or bond layers of material (adhesives, varnishes, barrier coatings) with micrometric precision. Surface quality and the regularity of the coating are decisive for the performance of the final material. Precision grinding of covered rollers ensures tolerances of ±0.01 mm and optimises the surface finish depending on the application.

Transport and tension rollers: Although sometimes considered less technical, they are crucial for guiding films and papers without wrinkles or tears. An unsuitable covering can cause slippage, marking or tension variations, directly affecting product quality.

Specific constraints in the packaging industry

High production speeds

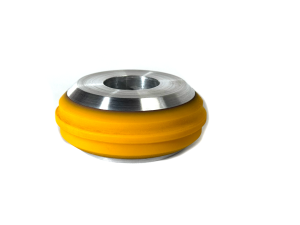

Some lines run at 400–600 m/min. Rollers must absorb friction and deformation without degrading. Polyurethane in the appropriate hardness range (70–95 Shore A) offers an excellent balance between mechanical resistance and flexibility.

Chemical exposure

Inks, solvents, adhesives or cleaning agents can attack certain elastomers. Silicone withstands a broad range of chemicals and keeps its properties over time. Nitrile, EPDM or Hypalon rubbers respond to more specific constraints. Identifying the substances involved is crucial to selecting the right material.

Surface requirements and precision grinding

Even a microscopic scratch on a coating roller can create defects over several kilometres of film. High-precision grinding (rectification) and surface-roughness control (Ra < 0.5 µm for smooth finishes, or textured for adhesion) ensure consistent coating quality and extend roller life.

Food-contact requirements

For food packaging, materials must comply with FDA or EU standards. Silicone and specific food-grade polyurethanes are formulated to meet these regulations.

Choosing the right material for each application

- Polyurethane: Versatile, abrasion-resistant, excellent mechanical strength, wide hardness range. Ideal for pull rolls, nip rolls and winding applications.

- Silicone: Essential for high-temperature processes (up to 200–300 °C) and compatible with many chemicals. Its low friction reduces marking and sticking.

- Rubber: Provides grip and elasticity. SBR, nitrile and EPDM formulations are selected according to technical requirements.

Profiles and surface finishes to optimise performance

- Crowning: compensates for roller deflection and ensures uniform pressure.

- Grooves: help evacuate air and prevent bubbles and surface defects.

- Embossing and texturing: improve grip and reduce slippage depending on the material and production speed.

Maintenance and roller service life

A well-maintained roller performs reliably even under intensive production. Recommended practices include:

- Regular cleaning using compatible products

- Visual inspection to detect wear or cracks

- Dimensional checks to monitor concentricity

- Keeping spare rollers for critical equipment

Optimise your packaging lines with ENRI

Choosing the right roller has a direct impact on productivity, product quality and maintenance costs. A precise analysis of the process: speed, temperature, chemical exposure and surface requirements, guides the selection of the optimal material, hardness, profile and finish.

For over 35 years, ENRI has helped packaging manufacturers optimise their rollers with strong technical expertise and in-depth knowledge of materials and processes. We provide long-lasting, custom solutions designed to meet evolving production speeds, material innovation and environmental standards.

Similar project in mind?

Our ENRI experts support you in creating your custom technical solutions.

Contact our experts →