Introduction

Due to their high performance and durability, silicones are among the most essential polymers. Their physical and chemical characteristics allow them to be used in multitude industrial activities, as well as everywhere in our daily lives.

Its remarkable resistance to temperature, to elongation, its resistance to tearing, its wide range of hardness, its antimicrobial, antistatic or food-grade properties characterise this elastomer, thus offering almost infinite application possibilities, in form of mastics, glues, joints, anti-foaming additives for washing powders, cosmetics, medical devices, insulating sheaths for high-temperature electrical cables, etc…

Their consistency varies from liquid (oils, implant) to hard plastic, resin, through gel and gum.

The basics of silicone

What is silicone?

Silicone definition and its chemical composition

While rubber is a purely organic compound, silicone elastomers (or polysiloxanes) are inorganic compounds formed from a chain of silicon and oxygen, in which groups attach to the silicon atoms. Certain organic groups can be used to link several of these chains. The most common type is linear polydimethylsiloxane (PDMS). The second group of importance is that of silicone resins, formed by branched or cage-shaped oligosiloxanes.

Origin and production methods of silicone

Pure silicon, the raw material of silicone, is obtained from quartz by electrometallurgy. This material is reacted in chemical reactors with methyl chloride to obtain methylchlorosilanes, the most important of which is dimethyldichlorosilane (DMDCS) – (CH3)2Cl2Si. Silicones are obtained by cross-linking to achieve the final properties of use. For this, a crosslinker is generally used, which is a specific multifunctional silane or silicone which can react with another silicone polymer. The crosslinking reaction is generally catalyzed and accelerated by heat, UV rays and humidity in the air.

Physical and chemical properties of silicone

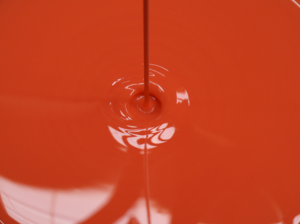

Due to their non-stick properties, silicone coatings offer excellent quality, especially while applied hot. This elastomer is characterized by remarkable properties: resistance to dry heat, permanent elasticity at wide ranges of high and low temperatures, resistance to ageing, ozone, conductivity electricity, good water resistance, gas impermeability, excellent sealing and weather resistance, low coefficient of friction, chemical inertness and biocompatibility, excellent fire resistance without toxic release, etc. …

Silicones are smart materials that offer reproducible, reversible, and large rapid change. For example, silicone changes its color under the effect of temperature. To achieve this effect, the formulation of the elastomer can be modified by introducing reversible phase change pigments, as a function of temperature.

Common applications of silicone in daily life

Silicone is found everywhere in our everyday life; In personal care and cosmetics, medical and biomedical applications, kitchen utensils and moulds, electronic, electrochemical and technological applications and many more.

Use of silicone in the industrial sectors

Silicones meet all the strict European standards and directives concerning food contact, which makes it possible to meet the high demanding needs of the food, medical and pharmaceutical sectors.

In the transport field, automobiles in particular and construction, they provide bonding solutions, often in extreme conditions, due to their resistance to temperature, cold or heat. Providing insulation properties, silicones are the chosen material when it comes to electrical cables and electronics.

They are also widely used for devices aimed for external use, due to the hydrophobic nature of their surface, allowing a very low level of leakage.

Silicone in the Food Industry

Heat resistant with an excellent reaction to adhesion, silicone is one of the most important elements that meets the food hygiene standards. The FDA-certified anti-adhesion silicones makes silicone widely used in the food industry. The heat resistance combined with a low surface tension is used in the context of mold release or anti-adhesion food applications and utensils.

Silicone in the healthcare (medical, biomedical, paramedical and pharmaceutical) industries

Its flexibility and resistance qualities and its behavior in the face of the sector’s hygiene requirements, make silicone the flagship material of the healthcare industry. Thanks to its excellent unique properties, chemical, thermal and mechanical, silicone is an integral part of the healthcare world. It meets a series of standards (FDA and ISO certified, among others), allowing its use in this constantly developing environment. Silicones are widely used today in medical, paramedical, pharmaceutical, parapharmacy and cosmetic applications, in particular for the fields of prosthetics and medical devices, such as hearing aids for example, podiatry, etc., requiring a very high level of safety, hygiene and quality standards.

Silicone in the transport industry

Comfort, design, quality and durability, coupled with safety and resistance to heat and smoke are just part of the constraints to be respected in the field of transport. Being able to answer those constraints, silicone is a key element in the transport industry. It is widely used in the automotive, aeronautical, aerospace, naval and railway sectors. Thanks to its unique characteristics and its excellent behavior, especially in the face of high temperatures, resistance to abrasion and aging, the use of silicone guarantees durability during use. This elastomer meets the particular needs of the industry requiring specific technical and chemical characteristics, such as a certain hardness, resistance to traction, tearing and sealing. Silicones are used for seals, bellows, hoses, bearings, wedging parts, exhaust systems and coatings to protect automotive surfaces and for applications in on-board electronics.

Silicone in the construction industry

Their low surface tension properties make silicone the first choice for anti-foam applications and for the structure of polyurethane foams control. Silicones are hydrophobic and thus widely used to protect buildings from moisture or damage caused by water penetration.

Among its uses in this industry, silicone is often used for facades waterproofing and construction joints, sealants, silicone-based adhesives and fire-retardant coatings and materials.

Silicone in the electronics industry

Thanks to their good resistance to climatic constraints coupled with good hydrophobic properties, silicones are used in the external insulation of high voltage electrical installations. They are essential when it comes to electrical cables and electronics, to provide electrical insulation properties.

Silicone uses in the electronics industry include encapsulation and protection of electronic components, electrical and thermal insulation, jointing and sealing of electronic circuits.

Other industrial uses of silicone

The low absorption of light in the UV-visible range 300-1300 nm makes silicone an asset for for optical transmission or transparency.

Their soft touch is an important factor when it comes to the widespread use of silicones as additives in cosmetic products or textile treatments, lubricants and mold release agents.

Silicone is also widely used in the petrochemical industry, due to its dynamic performance characteristics.

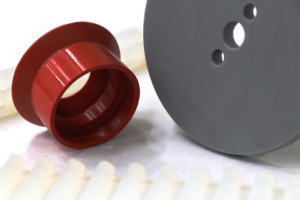

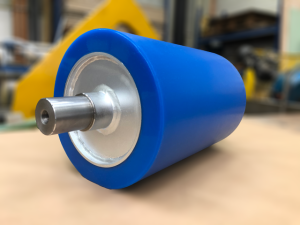

ENRI: your expert silicone coating manufacturer

At ENRI, we offer you the design and realization of your silicone rollers, cylinders, wheels and pulleys for any industrial application (Presser, Applicator, Transfer, Adhesive, Conical, etc.), intended for different markets, such as agriculture and the food industry, packaging (cardboard, packaging, plastic film, etc.), energy and raw materials (industry of wood, glass, petrochemicals and chemicals, steel, nuclear, etc.), printing and graphic arts, transport or industrial maintenance. Our silicone formulation is made according to your specifications.

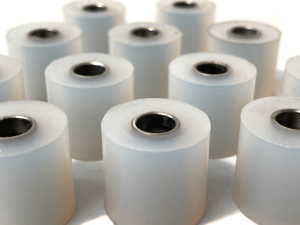

Production of custom-made technical parts in silicone

With more than 35 years of experience, ENRI offers you its know-how in the implementation of silicones. Our workshops are equipped with all the necessary technology for molding, spraying, casting, injection of a wide range to manufacture silicone coatings for your parts, according to your plans and specifications.

ENRI is also able to offer you a wide range of tailor made highly resistant technical articles molded in silicone, and for the different sectors. Among our articles: rods and ropes, profiles, discs, plates and sheets, bands, seals, sheaths and sleeves, bellows, suction cups, molded parts, flexible pipes, membranes and special coatings.

Conclusion

In this article, we have highlighted the different applications of this flagship material in our daily and industrial life and its importance for our society.

Silicone is a highly durable element: It also contributes to sustainable development by improving the energy consumption of applications in which this material is used.

The silicone industry is showing signs of great activity where many applications involving new materials continue to emerge. Important to mention in this context the emerging trends with the new technological challenges, increasingly moving towards connected and intelligent materials, objects or textiles, particularly in the energy and healthcare sectors.

Silicones continue to develop today both in terms of their synthesis processes and for their often very high value-added applications and can be more and more able to meet the needs of cost, respect for the environment and special needs.

At ENRI we continue to deepen our mastery of silicone, the key material of our company, in the process of our rollers and pulleys coatings and in the manufacture of our custom technical parts.

Sources

https://new.societechimiquedefrance.fr/wp-content/uploads/2019/12/frances-hd.pdf