Introduction: Why Roller Coatings Matter

In modern industry, maintenance teams, technical managers, and workshop supervisors often face recurring challenges on their production lines:

- Rapid roller wear

- Excessive slippage

- Material build-up

- Loss of mechanical precision

- Failures caused by heat

These issues directly affect product quality, productivity, and operating costs.

But here’s the good news: In most cases, the solution isn’t to replace the machine – it’s to adapt the coating of your rollers or specific technical components.

Did you know?

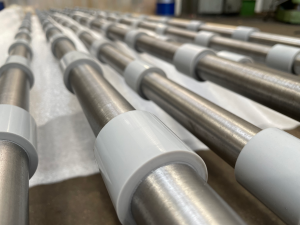

A well-coated roller can extend the life of an aging machine and prevent costly replacements. In many cases, the right elastomer coating can significantly improve your line’s overall performance.

Your Main Goals Are Clear

✔ Find a reliable solution to extend equipment lifespan.

✔ Ensure better grip, resistance to heat, abrasion, and chemicals.

✔ Reduce downtime and material losses.

Pro Tip:

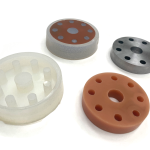

Coatings are never one-size-fits-all. Each process, material, and mechanical requirement needs a specific elastomer. That’s why a customized approach is essential.

Common Roller Problems – and How ENRI Solves Them

Identify. Understand. Solve.

| Problem | Probable Cause | ENRI Solution |

| Rapid roller wear | Abrasion from processed materials or high rotation speeds | Polyurethane (PU) coating adapted to load and type of contact |

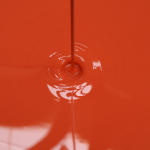

| Adhesive or material sticking | Lack of anti-stick properties | Silicone coating or special anti-adhesive treatment |

| Slippage or poor grip | Inadequate friction coefficient or overly smooth roller | Natural rubber or Nitrile coating with specific finish |

| Exposure to high temperatures | Intense thermal environment or hot materials | High-temperature silicone coating or EPDM |

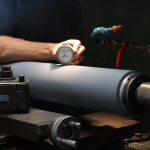

| Need for high mechanical precision | Tight tolerances or flatness requirements | Precision grinding, dimensional control, and custom finishes |

| Excessive production noise | Poor vibration absorption or unsuitable material | Specific elastomer coatings for vibration reduction |

| Irregular material traction or slippage | Inadequate surface or wear | Controlled-friction coating |

| Localized roller overheating | Excessive friction or thermal environment | Heat-resistant coatings: high-temp silicone or EPDM |

| Chemical incompatibility | Exposure to solvents, oils, or other chemicals | Materials resistant to chemical corrosion |

| Switching to a new material | Insufficient adaptation to new constraints | Customized study and coating adaptation |

| Need to increase equipment lifespan | Premature wear, unsuitable coating | Tailor-made coatings, preventive maintenance, rigorous QC |

| Compliance with sector standards | Regulatory or market-specific requirements | Coatings compliant with food-grade and industry-specific standards |

Pro Tip:

Choosing the right coating simplifies maintenance. Fewer breakdowns mean more uptime, lower costs, and higher productivity.

Why Work with ENRI? The Benefits of a Tailor-Made Approach

ENRI doesn’t just supply coatings—we deliver complete technical solutions. Our approach ensures:

✔ Optimized production: Less waste, better quality, and minimal downtime.

✔ Extended durability: Proper coatings prolong roller and machine life.

✔ Lower costs: Simplified maintenance and stable performance over time.

Conclusion

At ENRI, we don’t just provide technical coatings.

We help you solve real problems on your production lines. By analyzing your industrial constraints, we develop customized solutions that combine performance, durability, and compliance.

Have an issue with your rollers or components in contact with your materials?

Let’s talk. The right coating can make all the difference.

Similar project in mind?

Our ENRI experts support you in creating your custom technical solutions.

Contact our experts →