ENRI in Action: Your Polyurethane Expert for Modern Industry

Introduction

At ENRI, we bring over 35 years of experience in the implementation of polyurethane materials. This essential component of modern industry allows us to develop with you the ideal elastomer for your most demanding industrial projects.

Polyurethane (PU) is now regarded as one of the most versatile and high-performance polymers on the market. In this article, we’ll give you a comprehensive overview of this exceptional material, illustrated by our recent projects and technical expertise.

What is Polyurethane?

Polyurethane is a polymer obtained through the reaction between a diisocyanate and a polyol compound. Depending on the formulation, it can take several forms: rigid foams, flexible foams, elastomers, coatings, adhesives, and more.

ℹ️ Info: The first polyurethane foams date back to the 1950s, but recent technological advances have taken it even further – notably with the development of “smart PU foams” designed for highly specific uses.

The Manufacturing Process

| Step | Description | Our Expertise |

|---|---|---|

| 1. Mixing | Combination of diisocyanates and polyols | Precise tuning of mechanical properties |

| 2. Pre-polymer | Beginning of exothermic reaction | Optimal control of material density |

| 3. Molding | Shaping (gravity casting, injection, bonding) | Custom fabrication of technical parts |

| 4. Finishing | Drying, cutting, or assembly | High-performance coatings |

Why Choose Polyurethane?

Polyurethane is at the core of our solutions due to its many technical benefits:

• Excellent resistance to wear, impact, and tearing

• Superior thermal and acoustic insulation

• Great vibration absorption and low deformation

• Excellent adhesion to metal surfaces

• Chemical resistance to harsh environments (oils, humidity, aggressive products)

• Wide range of hardness levels and finishes

• Flexible formulations (rigid, semi-rigid, elastomeric)

• Option for eco-friendly formulations (bio-based PU)

💡 Tip: If you’re looking for a material suitable for extreme conditions (humidity, heat, corrosion), polyurethane often stands out for its longevity and efficiency.

Our Latest Polyurethane Projects

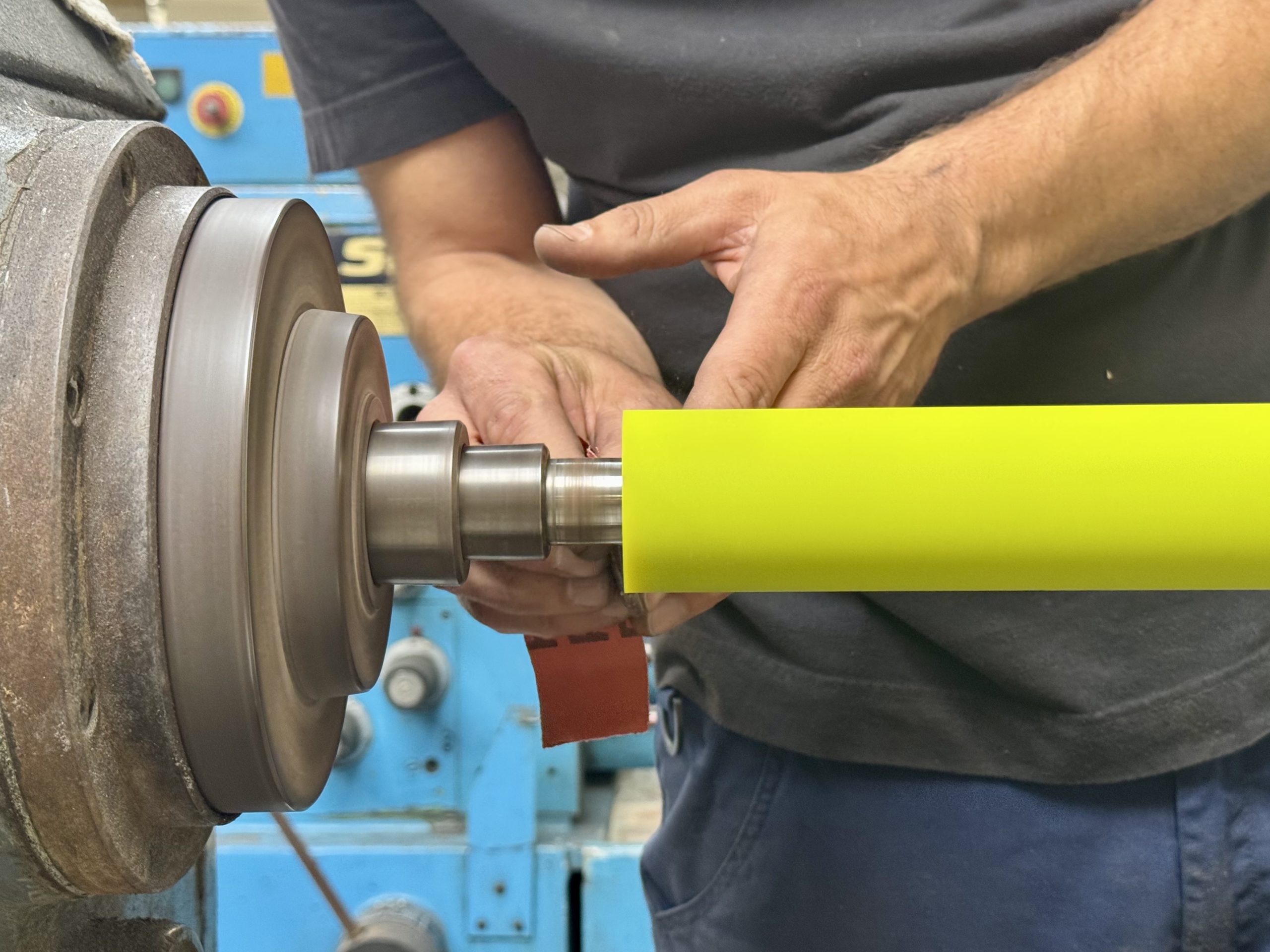

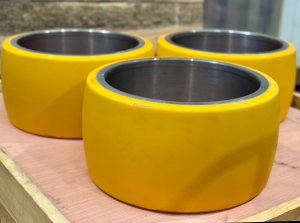

1️⃣. Rollers and wheels for custom machines

Sector: Custom industrial machine design

Features: Custom shapes and dimensions, high load and wear resistance

Benefits: Enhanced durability and reliable performance under heavy-duty use

2️⃣. Bio-based rollers for electronics

Sector: Electronics and diverse industries

Features: Partially bio-based PU, high precision, chemical compatibility

Benefits: More sustainable alternative, reduced carbon footprint, preserved performance

3️⃣. Wheels for oil & gas and water sectors

Sector: Energy, petrochemical, water treatment

Features: Resistance to hydrocarbons, moisture, and high mechanical stress

Benefits: Longevity and safety under extreme conditions

4️⃣. Conical rollers for metallurgy

Sector: Metallurgy

Features: Custom conical shapes, high abrasion resistance

Benefits: Optimized guidance and increased endurance on production lines

5️⃣. Wheels for the energy sector

Sector: Wind, hydro, thermal, oil & gas

Features: Resistance to heavy loads, impact, and outdoor environments

Benefits: Reliability and long service life, even in challenging conditions

Wide Industrial Applications

Our areas of polyurethane expertise at ENRI:

• Industrial rollers for metallurgy, plastics, printing, and more

• Specialized rollers for textiles and custom machinery

• Wheels and rollers for energy, petrochemicals, and materials handling

• Custom technical parts tailored to specific needs

Eco-Responsible Innovations

With increasing environmental concerns, ENRI is moving toward more sustainable solutions:

• Low-VOC formulations: Reduce impact on health and the environment

• Bio-based raw materials: Use of vegetable oils to partially or fully replace petrochemical components

• Recycling and recovery: Development of chemical and mechanical recycling methods to extend product life

• Smart foams: Adaptive properties to improve energy management and thermal performance

⚠️ Warning: Regulations are evolving quickly (environment, safety, etc.). Before investing in a PU solution, always check the current standards and certifications relevant to your industry.

How ENRI Innovates with Polyurethane

We offer:

• Custom coatings: Adapted for various sectors (food, logistics, textiles…)

• High-performance polyurethane adhesives: For increased strength and durability

• Eco-friendly solutions: Low-VOC formulas and optimized manufacturing processes

• Ongoing R&D: To develop smart PU foams and innovative coatings

❗Important: At ENRI, we test and validate our products according to strict protocols to ensure compliance with environmental and industrial standards.

Polyurethane FAQ

Polyurethane is a polymer resulting from the reaction between a diisocyanate and a polyol. It can take many forms (foams, elastomers, resins) and is used across sectors such as automotive, construction, and food processing.

2. What are the benefits of polyurethane coatings?

Polyurethane coatings are known for their high resistance to abrasion, impact, and moisture. They also offer excellent thermal and acoustic insulation and long-lasting durability.

3. Are polyurethane adhesives suitable for all materials?

Polyurethane adhesives bond to a wide range of substrates (metal, wood, plastic, glass). Their flexibility and strength make them ideal for demanding industrial assemblies.

4. Why choose ENRI for your polyurethane applications?

ENRI focuses on innovation, quality, and environmental compliance. We offer custom and eco-responsible solutions tailored to our clients’ needs- whether for technical parts or roller coatings.

Conclusion

These recent projects demonstrate ENRI’s ability to deliver tailored polyurethane solutions, meeting the diverse requirements of our clients while addressing today’s environmental challenges.

Thanks to its exceptional mechanical properties, flexibility, and durability under extreme conditions, polyurethane offers countless possibilities. We support you from the initial brief to the delivery of optimized, robust, and long-lasting parts- all in full compliance with the strictest standards.

Got a project in mind?

Contact our team for a personalized assessment or quote. We’d be happy to discuss your industrial needs and propose the polyurethane solution best suited to your goals.

Thank you for reading!

Feel free to share this article if you know professionals who may be interested in polyurethane.

Optimize your industrial performance

Discover how our solutions can improve the efficiency of your equipment.

Contact our experts →