At ENRI, we master every stage of roller covering, from design to delivery, with the same commitment to quality, traceability, and performance.

Discover how our expertise is applied concretely, from material selection to final finishing.

Understanding Roller Covering

Roller covering (or roller recovering) consists of applying an elastomer coating, such as silicone, rubber, polyurethane (PU), or composite, onto a metal core to improve its performance and extend its service life.

This process is essential across many industries, including printing, plastics processing, metallurgy, energy, food production, packaging, textile, etc.

Each type of elastomer has specific properties:

- Rubber: versatile, with good chemical resistance.

- Polyurethane (PU): excellent abrasion and tear resistance.

- Silicone: high temperature resistance and food-grade compatibility.

The choice depends on the application, the hardness of the coating (ranging from 5 to 98 Shore A), and the production environment.

We can also manufacture specific coatings in Shore D hardness.

This hardness directly affects the adhesion, deformation under load, and energy restitution of the roller.

Needs Analysis and Co-Engineering

Every project begins with a detailed study of the client’s technical specifications, including mechanical, chemical, thermal, and dimensional constraints.

Our engineering department works closely with clients to:

- Conduct feasibility and material studies,

- Design prototypes and simulations,

- Validate performance through laboratory testing.

This co-engineering phase ensures a customized, optimized solution for every production line.

Preparation, Stripping, and Coating Application

ENRI works on both new and used rollers as part of stripping and reconditioning operations.

The old coating is carefully removed to preserve the metal core, followed by key preparation steps:

- Chemical degreasing,

- Abrasive blasting (sandblasting or shot blasting) to create surface roughness,

- Dimensional inspection before applying the new coating.

Depending on the selected material, different processes may be used:

- Compression, injection, or transfer molding,

- Polyurethane casting,

- Elastomer or silicone wrapping,

- Press or autoclave vulcanization.

Vulcanization parameters (temperature, pressure, duration) are precisely adjusted according to the elastomer type and coating thickness to ensure perfect adhesion and uniform mechanical properties.

Grinding and Quality Control

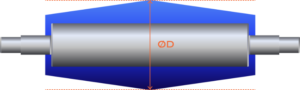

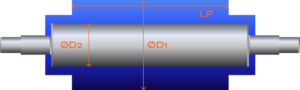

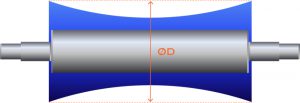

After coating, each roller is ground to final dimensions with a precision of up to ±0.05 mm.

Quality control includes:

- Dimensional measurements, hardness, and surface roughness,

- Adhesion tests,

- Dynamic balancing.

Depending on the application, we can also produce special surface profiles, such as crowning, grooves, or custom textures, tailored to your specific needs.

Each roller is accompanied by a complete traceability record, documenting every operation and inspection performed.

Lead Times, Packaging, and Delivery

Manufacturing lead times vary depending on the project’s complexity.

For urgent requests, an express service can be offered upon availability.

Before shipment, rollers are carefully protected and packaged.

We can also supply ISPM 15-compliant wooden crates for export.

Each delivery is tracked from our workshop to your facilities, ensuring complete reliability.

Good to Know

Proper storage (protected from UV and high temperatures) and regular inspections significantly extend the service life of covered rollers.

Planning roller recovering cycles also helps prevent unscheduled production downtime.

Innovation and ENRI Expertise

For over 35 years, ENRI has continuously invested in R&D and training to anticipate industrial needs.

Our deep knowledge of elastomers and in-house manufacturing processes allows us to deliver custom, high-performance, and durable coatings, tailored to the most demanding operating conditions.

ENRI, Your Technical Partner

From first contact to final delivery, our commitment remains the same: quality, precision, and reliability.

Our roller covering solutions ensure every customer receives a roller built to last and to enhance the performance of their industrial equipment.

Optimize your industrial performance

Discover how our solutions can improve the efficiency of your equipment.

Contact our experts →