In the food processing industry, industrial rollers play a critical role in the reliability of production lines. Depending on equipment configuration, rollers may be in direct contact with food products or operate in product proximity zones within a strictly regulated environment.

The selection of a roller covering must address both the mechanical constraints of the process and the applicable food-contact regulatory requirements. When specified in the technical documentation, the use of a food-grade elastomer compliant with recognized international regulations becomes a key parameter.

Several elastomer families may be selected depending on the application, including food-grade silicones for their thermal stability and non-stick properties, polyurethanes for their mechanical strength and abrasion resistance, as well as specific rubber compounds suited to particular operating environments.

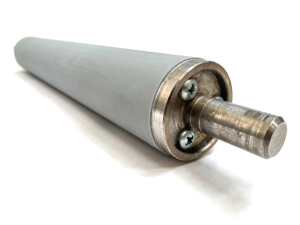

Depending on the application, rollers may be manufactured in carbon steel or stainless steel for direct contact zones and complemented by elastomer coverings designed to meet the mechanical demands of the production line.

At ENRI, roller coverings for food processing applications are formulated using raw materials compliant with the relevant regulatory frameworks, including FDA 21 CFR 177.2600, Regulation (EC) No 1935/2004, or other applicable standards depending on the project and destination market.

Food-Contact Regulatory Framework

FDA 21 CFR 177.2600

This U.S. regulation governs rubber articles intended for repeated use in contact with food. It defines:

- Authorized polymers

- Permitted additives and fillers

- Extractable limits following migration testing

- Testing conditions using various food simulants

An FDA-aligned formulation relies on the use of raw materials listed within this regulation and supported by appropriate documentation.

Regulation (EC) No 1935/2004

Within the European Union, Regulation (EC) No 1935/2004 requires that materials intended to come into contact with food:

- Do not transfer substances in quantities that could endanger human health

- Do not alter the composition of the food

- Do not adversely affect its organoleptic characteristics

It is complemented by Regulation (EC) No 2023/2006 on Good Manufacturing Practice (GMP). Compliance depends not only on formulation but also on traceability and controlled manufacturing processes.

BfR Recommendation XV

For silicone elastomers, BfR Recommendation XV serves as an additional technical reference widely recognized in European markets. It specifies authorized substances and particular requirements applicable to silicone materials.

Understanding and integrating these regulatory requirements is essential when designing roller coverings for food processing equipment.

Food-Grade Silicone vs. Standard Industrial Silicone

Food-grade silicone and standard industrial silicone share a similar polysiloxane base chemistry. The difference lies in the selection of raw materials, additives, pigments, and curing systems.

For food processing applications, the formulation must comply with applicable food-contact regulations relevant to the destination market. Batch traceability and supporting documentation are essential components.

A post-curing process is systematically applied to our food-grade silicones in order to stabilize the material prior to commissioning and to reduce potentially extractable residual compounds.

Roller Applications in the Food Processing Environment

Rollers with food-grade elastomer coverings are used across a wide range of food processing lines, including bakery, confectionery, dairy processing, meat processing, and food packaging.

Bakery and Pastry Production

In industrial bakery operations, rollers are used for conveying leavened dough products such as baguettes, croissants, and brioche. These applications may involve variable thermal environments due to proximity to baking equipment.

Silicone is valued for its non-stick behavior and stable performance in warm conditions. Hardness ranges between 40 and 55 Shore A are frequently selected to preserve delicate, deformable products while ensuring consistent traction.

Confectionery and Chocolate Processing

In confectionery and chocolate processing, rollers are exposed to products rich in fats and sensitive to surface marking. Surface finish control is critical to prevent visible marks on the finished product.

Temperatures vary depending on the process stage. Food-grade silicone provides good resistance to fats and sugars and stable performance under these conditions. Hardness levels between 55 and 65 Shore A are commonly used depending on mechanical constraints.

Dairy Processing

In dairy environments, rollers are mainly involved in conveying, cutting, bottling, capping, and labeling operations.

Even when the elastomer covering is not in direct contact with the food product, equipment operates under strict hygiene requirements, frequent cleaning cycles, and slightly acidic atmospheres. Selecting a compliant covering contributes to securing the overall production process.

Meat Processing Industry

Cutting, portioning, and packaging lines require regular cleaning and involve exposure to environments rich in proteins and animal fats.

Properly formulated food-grade silicone or other suitable elastomers can meet these constraints under validated operating conditions.

Food Packaging

Rollers are also used in the production or processing of materials intended for food contact, such as films, trays, and packaging lines.

Material compliance contributes to securing the entire chain, from processing through to final packaging.

Hygiene Considerations

Food processing environments require strict hygiene protocols. Roller coverings must maintain their mechanical properties despite repeated cleaning operations.

Selecting the Right Covering for Food Processing Rollers

Hardness

For most food processing applications, hardness levels between 40 and 70 Shore A cover the majority of needs:

- 40–50 Shore A: fragile products requiring gentle contact

- 55–60 Shore A: balanced compromise between flexibility and mechanical strength

- 65–70 Shore A: higher loads or increased mechanical stress

The final selection depends on dynamic behavior, contact pressure, and production line parameters.

Color

Color may serve practical purposes. Blue is frequently selected because it facilitates visual detection in case of wear or fragmentation. White remains common in certain food processing environments.

ENRI Solutions for the Food Processing Industry

ENRI designs and manufactures roller coverings tailored to food processing environments, integrating food-contact regulatory requirements when specified in the technical brief.

The systematic post-curing of our food-grade silicones, batch traceability, and supporting documentation support compliance with international quality standards.

Beyond elastomer coverings, ENRI also manufactures and refurbishes steel and stainless steel rollers for food processing lines. We operate in sectors including potato processing, coffee roasting, abattoirs, as well as cutting, sorting, bottling, capping, and labeling operations.

Controlling both the metal core and the elastomer covering ensures overall technical consistency of the roller assembly, from both mechanical and regulatory perspectives.

Our product ranges include:

- RISIL food-grade for environments requiring high thermal stability and non-stick performance

- RITHAN formulated for food applications where enhanced abrasion and mechanical resistance are required

- RIBBER solutions adapted to specific operating environments

Each project is evaluated according to its technical specifications to ensure material compliance and suitability under real operating conditions.

Conclusion: Mastering Roller Coverings in the Food Processing Industry

In food processing environments, roller performance does not rely solely on the selected material, but on the alignment between formulation, manufacturing process, post-curing, and actual operating constraints.

Whether using food-grade silicone compliant with international regulations or other suitable elastomers, the objective remains the same: ensuring long-term equipment reliability and meeting the regulatory and audit requirements of the sector.

Optimize your industrial performance

Discover how our solutions can improve the efficiency of your equipment.

Contact our experts →