Surface Features of the Rollers

ENRI is not officially ISO certified, but all of our products are created in keeping with the latest ISO standards and meet a wide range of quality criteria.

The surface of the conveyor rollers, in particular, is subject to a great deal of attention. According to ISO 6123-2: 1988 (E), the surface of the roller cover is defined according to its intended use. It should be characterized either according to a type of surface treatment or according to the maximum value of surface roughness, as agreed between the parties.

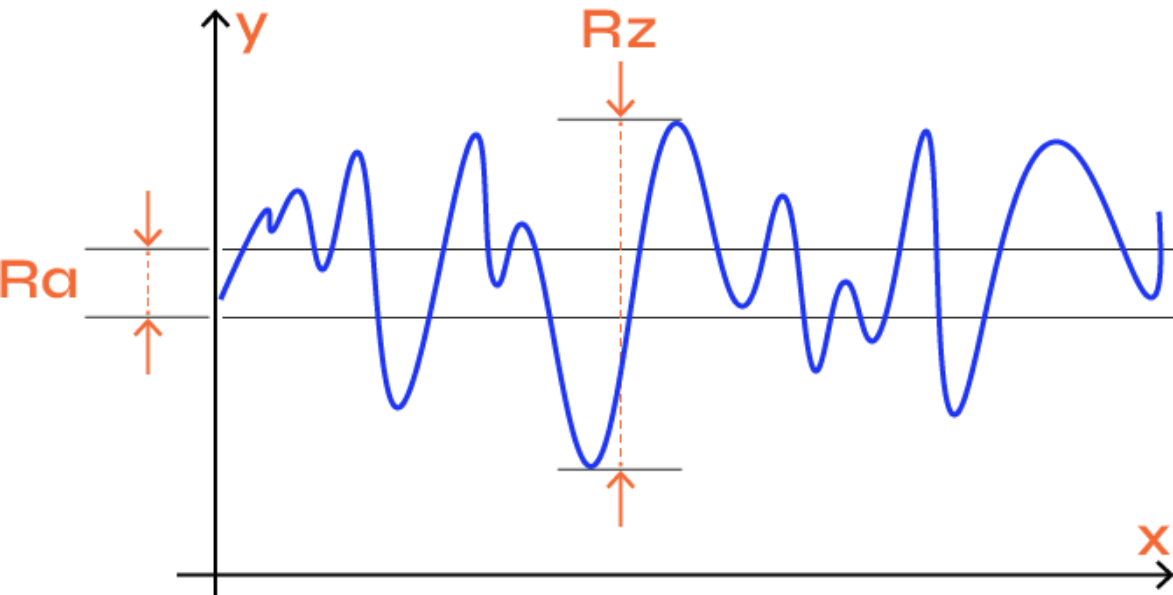

Measurement of Roughness

profile, in micrometers (μm)

· Rz: Average height of irregularities over

5 points, in micrometers (μm)

Relationship Between Hardness and Roughness

An important factor in terms of choosing the material, hardness is used to define the resistance of a material, in relation to the penetration of a harder body. Hardness is measured with a durometer (hardness tester) and can be expressed in different scales of measurement: Shore A, Shore D.

Possible Finishing

There are several types of surface finishing, each corresponds to the surface’s treatment:

Polished Finishing

For soft elastomers, the surface is smooth like velvet; for hard rubber (ebonite) or plastic, it is smooth and soft. Grinding marks are not supposed to be visible to the naked eye. Sporadic grinding marks are tolerated. Such a finishing is not possible for all material qualities.

Fine Grindstone Finish

Slight grinding marks are visible to the naked eye but cannot be felt.

Standard Grindstone Finish

Slight grinding marks are visible to the naked eye and to the touch of the roller.

Mill Finish

The surface is only processed, with as little flux from the machining tool as possible. The machining grooves are visible and can be detected by touching the roller.

Raw Finish

The roller’s surface has not been treated or coated in any way, such as a marked fabric roll surface as it emerges from the vulcanization process or a plastic-coated roll.

Special Processing

It applies for surface finishes other than polished and rough ones, for example for a high-end plastic-coated roller, or for a finish for specific applications with a special structure (service previously agreed between the parties).